RFID Product Overview

Our HF-band IC tags are manufactured in our own self-developed facilities, which allows us to accept orders and prototypes in small lots.

We can also customize the size, shape, and resonance frequency according to your requests.

Basic IC tag specifications

| Standard | ISO15693, ISO14443/TypeA |

| Operating frequency | HF band (13.56MHz) |

| Antenna Type | Copper wire coil antenna |

| Heat Resistance Temperature | 100°C to 200°C (depending on the exterior material) |

| Possible molding dimensions | Diameter: Φ5.5 to Φ75 |

| Outer Material | PET, PEN, PPS resin, synthetic paper, PET seal, silicone, epoxy, etc. |

| Product Color | White, black, milky white, printing ( various colors available) |

| Communication distance | 5 to 150 mm (measured with Takaya Corporation's 100 mW reader/writer TR3-D002A) Reference value |

Selectable IC Chip

| IC Chip Product Name | User Memory | Max. number of writes | Data Retention Period | Standard |

| I-CODE SLI | 112(byte) | 100,000 times | 10 years |

ISO/IEC 15693, 18000-3 |

| I-CODE SLIX | 112 | 100,000 times | 50 years | |

| Tag-it HF-I Pro | 32 | 100,000 times | 10 years | |

| Tag-it HF-I Standard | 32 | 100,000 times | 10 years | |

| MB89R119B (FRAM) | 256 | 1 trillion times | 10 years | |

| MB89R118C (FRAM) | 2000 | 1 trillion times | 10 years | |

| Mifare Classic 1K | 1024 | 100,000 times | 10 years |

ISO/IEC 14443A |

| Mifare Ultralight | 48 | 10,000 times | 5 years |

ISO/IEC 14443A, NFC Forum Type2 |

| NTAG213 | 144 | 100,000 times | 10 years | |

| NTAG215 | 504 | 100,000 times | 10 years | |

| NTAG216 | 888 | 100,000 times | 10 years |

(Note)

・Consult with us for production of IC chips other than those listed above. We will discuss MOQ lot numbers with you for certain types of IC chips.

・Communication range depends on reader/writer performance, tag antenna size, operating environment, etc.

・I-CODE SLI is a registered trademark of NXP Semiconductors, Inc. All other company and product names are trademarks or registered trademarks of their respective companies.

Product Category

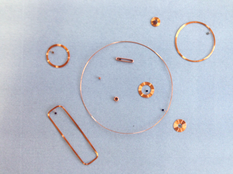

IC Tag Inlay

Wire-wound antennas are easily customized in size and shape to suit a wide variety of applications.

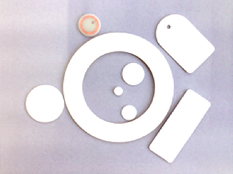

Laminate IC tag

A wide variety of outer materials such as PET, PEN, and labels (synthetic paper) can be produced.

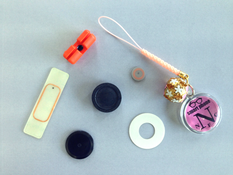

Metal-compatible IC tag

We offer a variety of IC tags that can be easily read and written even when attached to metal surfaces.

Special IC tag

This product line includes chemical-resistant IC tags, heat-resistant IC tags, IC tags for tableware management, and other specialized applications. Customized products are also available.

Introduction of Manufacturing Technology

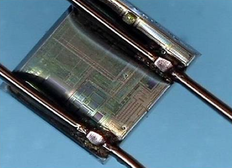

Ultra-compact antenna winding technology

An antenna manufacturing method based on micromotor precision winding technology is used to coil copper wire with a diameter of around 0.07 mm, which is thinner than a human hair. This has realized a compact, high-precision antenna coil.

※Photo: World's smallest class 1 mm square IC tag

Antenna direct bonding technology

The connection between the IC chip and antenna is the key to IC tag performance. We directly bond the IC chip bump and antenna by alloying them together (patented). This enables IC tags to be smaller and more durable* at the same time.

※Proven record of use at a maximum temperature of 200°C.

In 2009, we received the Award for Excellence in the Product and Technology Development Category of the 3rd Monodzukuri Nippon Grand Awards sponsored by the Ministry of Economy, Trade and Industry.

(Project name: "Ultra-fine wire winding technology enables IC tags to be made smaller, more precise, and lower in price at the same time")